Hardware specification

| deutsch | english | español | français | italian | 日本語 | 한글 | português | русский indonesia | HowTo [ID# 59431] +/- |

Contents

Laptop Hardware

The XO laptop is the center of One Laptop Per Child. After two years of development, it is approaching mass production, with several thousand Beta test (B2) units deployed to developers and for testing in schools in participating countries. The laptop design has just undergone a final minor update to keep up with advancements in technology.

Specifications

- Graphics Controller: Integrated with Geode CPU; unified memory architecture

Physical dimensions:

- Dimensions: 242mm × 228mm × 30mm (approximate, subject to change)

- Weight: Less than 1.5 kg (target only — subject to change)

- Configuration: Convertible laptop with pivoting, reversible display; dirt and moisture resistant system enclosure

Core electronics:

- CPU: AMD Geode LX-700@0.8W (datasheet)

- CPU clock speed: 433 MHz

- Compatibility: Athlon instruction set (including MMX and 3DNow! Enhanced) with additional Geode-specific instructions

- North Bridge: PCI and Memory Interface integrated with Geode CPU (info)

- Graphics Controller: Integrated with Geode CPU, using a unified memory architecture

- South Bridge: AMD CS5536 (datasheet)

- DRAM memory: 256 MiB dynamic RAM

- Data rate: Dual – DDR333 – 166 MHz

- BIOS: 1024 KB SPI-interface flash ROM; LinuxBIOS open-source BIOS; Open Firmware bootloader

- Mass storage: 1024 MiB SLC NAND flash, high speed flash controller

- Drives: No rotating media

- Embedded Controller: ENE KB3700

- CaFE ASIC (Camera, Flash Enabler chip, provides high performance Camera, NAND FLASH and SD interfaces). Marvell 88ALP01: CaFE Specification

Display:

- Liquid-crystal display: 7.5” Dual-mode TFT display

- Viewing area: 152.4 mm × 114.3 mm

- Resolution: 1200 (H) × 900 (V) resolution (200 dpi)

- Mono display: High-resolution, reflective monochrome mode

- Color display: 800 (H) x 600 (V) or greater transmissive color mode

- Power Consumption: 0.1 Watt with backlight off; 0.2-1.0 Watt with backlight on

- The DCON - Display Controller chip with memory that enables the display to remain live with the processor suspended. The display and this chip are the basis of our extremely low power architecture. The machine is usable and relaying mesh networking traffic while the CPU and much of the motherboard is regularly turned off. The display controller chip also enables deswizzling and anti-aliasing in color mode. You can examine this photograph of the display (it looks even nicer in person; photographing a display is remarkably difficult).

- Note: web browser images are currently scaled up so that an image of very roughly [800x600] fills up the browser window.

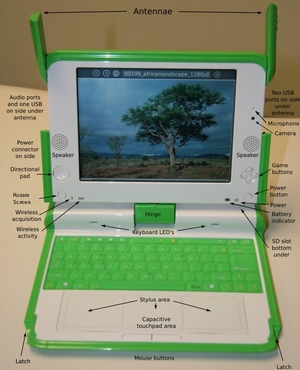

Integrated peripherals:

- Keyboard: 70+ keys, 1.2mm stroke; sealed rubber-membrane key-switch assembly

- Keyboard Layouts

- Layout pictures (for B3)- US International, Thai, Arabic, Spanish, Brazilian Portuguese, Nigeria, Urdu, French

- Cursor-control keys: five-key cursor-control pad; four directional keys plus Enter

- Touchpad: ALPS Electric Dual capacitance/resistive touchpad; supports written-input mode

- Audio: Analog Devices AD1888, AC97-compatible audio codec; stereo, with dual internal speakers; monophonic, with internal microphone and using the Analog Devices SSM2302 for audio amplification

- Wireless: Marvell Libertas 88W8388+88W8015, 802.11b/g compatible; dual adjustable, rotating coaxial antennas; supports diversity reception

- Status indicators: Power, battery, WiFi; visible lid open or closed

- Video camera: 640x480 resolution, 30FPS, Omnivision OV7670. The camera and device driver support disabling AGC and automatic color balancing, to enable its use as a photometric sensor for educational applications.

- Independent and undefeatable by software display of microphone and camera recording status

External connectors:

- Power: 2-pin DC-input, 10 to 20 V usable input. Input can safely handle -40 to 39 V. input. Exceeding this range will likely blow a one-time fuse.

- Line output: Standard 3.5mm 3-pin switched stereo audio jack

- Microphone: Standard 3.5mm 2-pin switched mono microphone jack; selectable input mode:

- Sensor, DC w. 2.5 V (3K ohm impedance) bias voltage for switches, resistive sensors, etc.

- Sensor, DC w. no bias voltage for measuring voltages (0 - 3 V)

- External Microphone, AC w. bias voltage

- Expansion: 3 Type-A USB-2.0 connectors; MMC/SD Card slot

- Maximum power: 1 A (total)

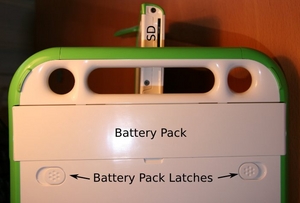

Battery:

- Fully-enclosed “hard” case; user removable

- Pack type: 4 Cells, 6V series configuration

- Two chemistries:

- NIMH, with a capacity of 16.5 Watt-hours

- LiFeP, with a capacity of 22 Watt-hours

- Electronics integrated with pack provide:

- Identification

- Battery charge and capacity information

- Thermal and over-current sensors along with cutoff switch to protect battery

- Cycle life: Minimum 2,000 charge/discharge cycles (to 50% capacity of new, IIRC).

- Power Management will be critical

BIOS/loader:

- Open Firmware is used as the firmware, including hardware initialization and fast resume.

Environmental specifications:

- Temperature: somewhere in between typical laptop requirements and Mil spec; exact values have not been settled

- Humidity: Similar attitude to temperature. When closed, the unit should seal well enough that children walking to and from school need not fear rainstorms or dust.

- Altitude: -15m to 3048m (operating), -15m to 12192m (non-operating)

- Shock: 125g, 2ms, half-sine (operating) 200g, 2ms, half-sine (non-operating)

- Random vibration: 0.75g zero-to-peak, 10Hz to 500Hz, 0.25 oct/min sweep rate (operating); 1.5g zero-to-peak, 10Hz to 500Hz, 0.5 oct/min sweep rate (nonoperating)

- 2mm plastic walls (1.3mm is typical for most systems).

Regulatory requirements:

- The usual US and EU EMI/EMC requirements will be met.

- The laptop and all OLPC-supplied accessories will be fully UL and is RoHS compliant.

Support Hardware

Serial Adapter

- 3.3V TTL to RS-232 Level shifter

Laptop Development Schedule

The XO laptop hardware development schedule has two more test unit builds (Beta Test 3 and Beta Test 4), before a final test build (C Test 1) on the final production line and mass production. The Beta Test 3 build scheduled for early May will be the first one providing the processor and memory capabilities of the production version.

Pre-production Test Systems (CTest-1, or C1)

This build is of 300 laptops produced as a test of the manufacturing process on the main production line, and should happen starting August 6th, 2007. Slip resistance rubber feet will be added as will more easily replacable bunny ears (just two screws per ear after bezel removal). The hinge stop that appeared in B3/B4 will be eliminated or reduced (this is used to the stop the display at perpendicular before it tilts back further). Bean texture will be applied to the exterior white parts and "satin" texture to the the rest of the laptop plastic parts. A C1 laptop will be nearly identical to the production unit ...

Beta Test 4 Systems (BTest-4, or B4)

This build which ran from June 20-25, 2007, was the final chance to fix hardware and mechanical problems that were detected in the Beta Test 3 build of the XO. 2000 units were built.

Texture was added to the upper handle bar, the hinge tilt was increased by 7 degrees, the hinge "squeak" was eliminated, the rabbit ears click in place when put in the "down" position", the slight camera vignetting seen in B3 was eliminated, and minor modifications were made to the motherboard.

Beta Test 3 Systems (BTest-3, or B3)

This build, scheduled for May 2007, is the first to use an updated design for the laptop. Noticeable improvements over BTest-2 include:

- A faster, lower power processor: the Geode LX-700

- 64 KB I/64 KB D of L1 Cache, 128 KB of L2 Cache (vs. 32 KB of L1 cache)

- Faster processor and memory clock (433/333 vs. 366/266)

- 1.5 W typ. vs. 3 W typ.

- Much better graphics processor, including support for rotated blits and depth conversion

- More memory: 256 MB of SDRAM (vs. 128 MB)

- extra screws

- insert molded rubber ears for better robustness

- a smaller battery cavity to improve robustness, make the bumper lines cleared

- 10-20V input voltage tolerance.

- new bumper tooling to allow the bumpers to be made of polycarbonate (as opposed to PC/ABS) with 3mm thickness and ribbing to 1.8mm (was 2mm and 1.2mm respectively)

- colored XO on the back cover (400 different color combinations so kids can distinguish their laptops from each other

- A keyboard that is much better to type on

- Finally a touchpad that is much easier to use and much more responsive

- a steel plate inside the entire keyboard base to reduce the feeling of flimsiness

- a flipped USB connector so each side has the same way up for a USB key or device

- A new hinge design allows greater tilt of the screen

- An improved case design (addressing strength)

A very small number of BTest-3 units (around a hundred) were built, all were used for hardware and low level software development.

Beta Test 2 Systems (BTest-2, or B2)

Approximately 2500 systems were built by Quanta and are being distributed. These are fully functional machines with CaFE ASICs, and reflect some, but not all of the learning and improvements from testing of BTest-1. Much more information about the BTest-2 systems can be found in the BTest-2 Release Notes. Some of the details of the hardware design are to support the OLPC Human Interface Guidelines.

BTest-2 systems are almost identical visually with BTest-1. BTest-3 will have more substantial physical differences. An easy way to tell the difference between BTest-1 and BTest-2 is that BTest-1 keyboards have white lettering, and BTest-2 has black lettering.

Beta Test 1 Systems (BTest-1)

Approximately 875 systems were built by Quanta and were distributed. These are fully functional machines, but built before the rigorous testing that will now take place. Much more information about the BTest-1 systems can be found in the BTest-1 Release Notes.

Pre-BTest boards

A small number of pre-BTest boards were built in preparation for building complete BTest systems. Developer information about B-test boards are here.

Alpha Test Prototype Electronics

Power up of the first OLPC electronics prototype boards occurred April 15, 2006. Power and ground testing continued over the weekend, and formal debug and BIOS bring up started Monday, April 17, 2006 at Quanta Computer's labs in Taipei, Taiwan. By Wednesday, April 19, Linux was booting on the first generation prototypes.

Photographs:

- Component side OLPC circuit board

- Back side of the OLPC circuit board

- Picture of Linux running with circuit board in the lab

- Picture of the screen of Linux running on the OLPC circuit board; fittingly, it shows a Chinese desktop

See also

Environmental Impact

Hardware

Support

Formerly part of this page:

Hardware uniqueness

Hardware design

School Server Hardware

While the laptop is rightfully at the center of OLPC, a valuable peripheral is the school server. OLPC will be building and distributing school servers along with the laptops, to extend the storage and computation provided by each laptop, as well as providing a local library and a mesh portal to the Internet.

Unlike the laptop, the school server is more of a collection of services than a hardware platform. In a manner identical to the laptop, OLPC will collaborate with manufacturing partners to provide a cost-efficient hardware platform for running the recommended software. Unlike the laptop, the manufacturing collaboration will not be exclusive. Individual countries will be free (even encouraged) to design and manufacture their own school servers running derivatives of the OLPC school server software.

XS

This will be the school server designed by OLPC. It is mostly designed, but currently on hold as we reconsider manufacturers, and should reach early production volumes in spring 2008. See the specification.

XSX

This is a prototype school server, built for early school trials in country. It will be integrated from off-the-shelf components, and will be overpowered compared to a production school server in order to simplify early demands for system software. See the specification and the implementation.