Measure/Activities/Magnets and Wire

Magnets and Wire

Build your own microphone. Build your own speaker.

This is a work in progress. I'll move it to its own page when we figure out how to structure the pages. Bill Wvbailey 17:21, 8 May 2008 (EDT)

The following demonstrates how a moving magnetic field "induces" (generates, creates a changing voltage, and vice versa: a changing voltage can induce motion. This is the fundamental principle behind the electric motor, the buzzer, the electrical relay (and the telegraph), the typical audio speaker and microphone (the telephone).

For someone who has never seen this demonstration, the following will be a real surprise – that something so simple/primitive can do so much.

Learning points:

- 1 Physics of electric induction – A changing magnetic field creates a changing electric field (voltage) that can move electrons in the vicinity -- in the case of copper wire the electrons are floating around loose inside the wire and the changing magnetic field causes them to move. (Why? Relativity: the effect is velocity-dependent. The faster the magnetic field changes, the larger the induced voltage.) Moreover the effect works in reverse: If electrons are moving they create a magnetic field. If they change their speed they cause a changing magnetic field -- this is the principle of the speaker.

- 2 Use the microphone “backwards” as a speaker (requires a source of sine waves: the laptop itself?) I’ve designed a sine wave generator (more accurately: a voltage-to-frequency converter) that does the trick nicely. More to follow on this.

- 3 Transformer (induction from coil to coil -- best demo requires a signal generator and two coils, but the 3.5KHz signal from the laptop is a quick demo):

- Use the coil of wire (no magnet necessary) to pick up a 3.5 KHz magnetic noise from the laptop itself, and see how to determine this mysterious signal with the Frequency activity (needs calibration of the X-axis -- the proposed sine-wave generator can do this. More to follow).

- What happens when an iron (steel) rod e.g. a screwdriver shaft is placed down the centers of both cores?

- 4 With sufficient amplification (need an amplifier, perhaps) can demonstrate “seismic rumble” etc.

- 5 Resonance (of tubes of different lengths). This should be quite apparent if we can come up with a decent signal generator.

- Reflections of waves: I've seen it happen, but need to figure out how to demonstrate it.

- 6 Microphone and speaker-cones: What is the optimal shape? I.e. to give you the loudest sound out aor the best microphone (think of: the RCA dog listening to his master's voice).

- 7 Resonators and oscillators (a guitar-wre can be excited by its own motion fed back to it – the analogy of a kid on a “swing” -- this will require some work)

- 8 Electromagnets: Make your own relay or telegraph? This requires a 1/4 "plug" of steel instered into the coil, and a U-shape piece of steel, too. (So does number 6, except a magnet needs to substitute for the steel core.) My first crack at this drew 1/2 amp of current and wasn't a very strong magnet. More work is required, may not be possible.

- 9 Earth's magnetic field ?? -- with a ~1000:1 amplifier (to be described here soon) I've been able to pick up stray magnetic fields (e.g. from an old Hewlett-Packard power supply) at a distance of 1-2 feet. I observed that if you move the coil (a 1000-turn coil, no core) back and forth not much happens. But if you rotate the core, the trace wiggles. Is this picking up the earth's magnetic field?

Quick description:

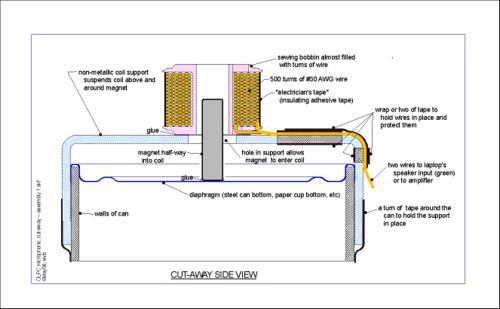

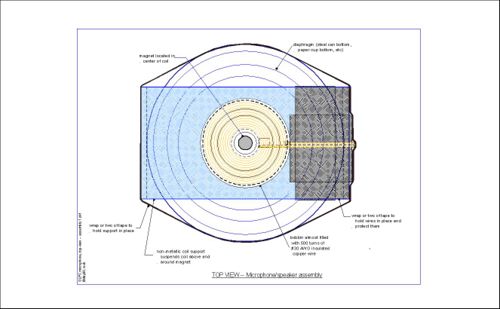

Glue a powerful-but-tiny cylindrical magnet end-up in the center of a steel can (paper cup, plastic cup). Locate a sewing bobbin, perhaps prep it with an extra hole (for the final wire), wind the bobbin with with insulated #30 AWG "magnet" wire (about 500 turns -- but any gauge that puts a couple hundred or more turns on will do). Rig up a support to hover the coil over (but not touching) the magnet + can, so that the magnet's end is about 1/2 way into the coil (learning experience here: why only 1/2 way? What happens if it is all the way in?). Strip the wire, connect to the microphone port and voila, you have a microphone. If you have a source of sine waves (square waves, etc) you can “drive” the coil and sound will come out the mouth of the can.

Stuff needed:

- Monaural or stereo audio plug

- Magnet about 0.187 inch diameter, 0.5 inch long. Magnet should be as strong as possible, but small enough to fit with a bit of clearance through the center-hole of the bobbin (see below). Magnet must be magnetized so that it has a north pole at one end and a south pole at the other end. Recommended part: Cyl0134 purchased from www.supermagnetman.com

- Alternately: a strong ceramic disk (i.e. rather flat) magnet will work, but less well than the longer magnet that allows us to insert only one pole into the coil. I've tried the following: longer if a steel “plug” is put into the bobbin’s center-hole. More work is required to test this out.

- Empty, clean steel can (“tin can”). My best luck has been with a Minute Maid, 6 oz Limeade (fruit juice) can.

- Alternates: Paper drinking cup (without wax on it), thin plastic container about 2-3 inches in diameter.

- ‘’Plastic’’(non-metallic) sewing bobbin (class 15 or class 66 type) with approximately ¼ diameter center hole (6.2 mm hole)

- Insulated copper “magnet” wire -- recommended is #30 AWG (American Wire Gauge). The mean length of turn is about 1.0 inch per turn, so 500 turns comes out to about 45 feet (15 meters). 500 turns will fit on the bobbin. Alternates: #28 AWG (coarser wire -- 300 Turns will fit on the bobbin), #34 AWG (much finer wire -- 1000 turns will fit on the bobbin). The fine wire becomes hard to wind and subject to breakage.

- Adhesive tape (recommended: "electrician's tape" -- a soft, stretchable, vinyl tape with googey-adhesive ; but any tape will do)

- ”Super glue” (methyl methacrylate glue), model glue, whatever...

- A non-metallic mechanical “support” to suspend the coil of wire (wound on the bobbin) over the magnet -- I found some 0.050 inch thick polystyrene at a model store and bent it. See the instructions.

Assembly instructions:

Winding 500 turns of thin is boring, but good for manual dexterity. It helps to put the spool of (source of) wire on a "mandrel" (e.g. a pencil through the spool) so that it unwinds as you wind the bobbin. And put a "mandrel" inside the bobbin so you can handle it easier. If you break the wire, try to repair with solder, and insulate the repaired place. Strip the insulation with some fine sandpaper, then "tin" the wire with flux-core solder and then solder the two wires together. (Or start over ... keep this coil with fewer turns for experiment -- what is the relationship between the number of turns and the strength of the microphone?).

The hardest part is fabricating a "support". Use non-metallic materials, relatively stiff (wood will work fine). The goal is a support that suspends the coil above and around, but not touching, the magnet. The support should be stiff enough, so that if you put a steel “plug” (more about the plug to follow) inside the bobbin's hole, the magnet cannot pull the coil+plug down and stick to the plug.

I started with a strip of polystyrene plastic, 1 inch wide by width-of-can+2 inches long, and fabricated this into a U, as follows. First I cut out the strip with scissors: I measured off approx. 1 inch, then about 0.050 inch (bend allowance), then the width of the can, then about 0.050 inch (bend allowance) and another 1 inch of plastic . In the center of this I drilled a 3/8 inch hole (to allow the magnet to pass into the center-hole of the bobbin).

To make the bends heated a thin (0.062 diameter) metal rod) over a gas flame so it is hot enough to melt the plastic but not burn it. Then I gently pressed the rod down, lengthwise over/along, a bend-allowance mark (i.e. where I wanted to bend the plastic). The hot rod melted the plastic about ½ way through. I then quickly bent the plastic up. As it hardened the plastic welded. (Do twice to form the U). Alternately, glue together the pieces.

The second hardest part is figuring out how to protect the thin wires from breakage. I had the wires come out the bottom of the coil, then run along the plastic support so I could cover them with the electrician's tape. I then cut the wires, stripped them with sandpaper for about 1/2 inch, tinned these 1/2 inch lengths, found some flexible wire, stripped and tinned it, soldered the flexible wire to the coil's wires, and protected the two joints with heatshrink tubing.

- There is an advantage to using soft, flexible wire -- the microphone is quite sensitive, and the wires will bang into it, causing spurious noise.

Run the laptop in AC mode with the DC bias off.

Build your own telephone

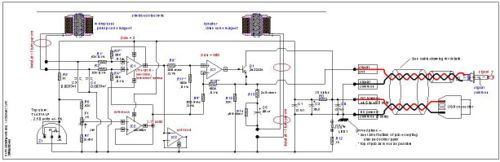

This is a fussier experiment. A one-way telephone requires two of the microphones described above plus a high-gain audio amplifier in between. One successful design I've tried for the amplifier follows the same design-concept as the "oscilloscope probe" described in Measure/Projects, but with two differential amplifiers. A balance must be struck in the design between a need for total high gain (e.g. between 1000 and 2500), errors caused by input-offset and gain-bandwidth, cost, complexity etc. The circuit shown does four things: (1) amplify the input, (2) move the "zero" of the signal "up" to 1.17 volts, thus placing the signal-trace in the center of the laptop's screen, (3) prove capable of driving into the laptop's 2000 ohm (2K) input impedance, (4) prove capable of driving the speaker coil with enough current.

The sound out isn't spectacular by any means, but it makes the point.

This "telephone" amplifier can also double as an amplifier for a signal generator, so the kids can see the signals on the screen as they hear the sound.

Teaching point -- Vibrating wires:

The amplifier permits a couple of spectacular teaching points. If we put the (1/2" long) magnet in the center of the coil, we can use the coil+magnet as a "probe" or "pick-up" to explore vibrating wires.

- For this experiment you won't need an amplifier. Put the laptop in AC mode, DC bias off. You will need just the coil of wire (500 turns of 30 AWG wire), a (4 mm (0.156 inch) x 1/2 inch-long) "rare-earth" magnet, a strip of paper, and a stretched steel wire of a string-instrument.

- I am currently researching what will happen with 5 and 6.2 mm magnets; also whether or not a U of steel bent around the coil, with a hole drilled in it for the magnet, will make this probe better. I believe the answer is yes...

For this experiment we proceed as follows:

- 1 Cut a strip of paper about 1 cm wide, about 25 cm long, and roll the magnet up inside the strip. It helps to tape or paste the magnet to one end of the strip and then roll it up. Then trim the strip's length away until the magent+paper "slug" fits into the coil snuggly.

- 2 To keep the magnet from being attracted to the wire and pulling out of the coil, put tape over the end of the magnet+coil that will be near the wire. The magnets are strong enough to actually stretch the wire and stick to it.

- 3 Find a stretched steel wire -- e.g. a guitar (I happened to have a dulcimer. This instrument turned out to be fortuitous because I could modify the coil's U-shapped support to suspend the coil+magnet above the wire 1-2 millimeters, and then slide the coil+magnet+support along the neck (which is attached to the sounding board) of the dulcimer. Anyway ... that's the notion I'm after here.)

- 4 Put the microphone coil+magnet "probe" up close to the wire (less than 0.1 inch/2.5 mm) and pluck the wire. Given the recommended magnet (0.5 inch long, 0.156 inch diameter rare-earth magnet) you should see sine wave(s) -- the fundamental and harmonics -- of the wire.

- Put the laptop into AC with the DC bias off, and a fair amount of "gain" (slider on the right side up 3/4 of the way). (A weaker alnico magnet may require the slider up further, or the amplification of the "telephone").

Teaching point -- Oscillators:

This experiment is fussy. You will need the "telephone" amplifer and two coils, both with magnets inside them. One coil is the "microphone-pickup", the other the "speaker-driver". Perhaps use the U-shaped supports, if they are long enough, to suspend each coil+magnet over the wire you want to vibrate (e.g. the guitar wire) -- it must not touch the wire, but should be a millimeter or two away from the wire.

- As noted, this experient is fussy to perform. Adequate amplification is required (I'm using about 2500:1 amplification; at 500:1 to 1000:1 the wire will vibrate, but only with some tweaking), a pickup coil with 1000 turns and the driver coil with 500 turns (I don't believe this matters too much). What is important is having powerful magnets and having these coils+magnets each close to the wire, but not actually touching it, getting the "phasing" of the coils right for either the fundamental or the harmonic, and getting the two coils placed correctly on the wire.

When you bring the two coils closer together, the trace on the laptop may "go nuts". This is the result of feedback -- the same thing that causes a microphone+amplifier+speakers in a concert hall to "go nuts" and squeel. In our case, if you put one coil 1/4 of the way from an end of the wire and the other coil 1/4 from the other end, you will excite the first harmonic (twice the frequency of the fundamental). To excite the fundamental, flip one of the coil's wires where they go into the amplifier. Now when close together they will not "go nuts", but when placed relatively close together in the center of the wire, the wire should vibrate in the fundamental mode.

Teaching point -- Resonance:

This experiment requires a signal generator with enough oomph to drive the "drive coil", and an amplifier. Put the drive-coil up to the wire and watch the amplified signal from the pick-up coil on the laptop. Space the two coils sufficiently apart to convince yourself that the pickup coil is simply not "seeing" the drive-coil -- i.e. place them at 1/4 the wire-length from each end of the wire. Then slowly "dial in" the frequency until the pickup coil begins to really hum. This can happen at the fundamental or any of its harmonics.