Talk:Battery and power: Difference between revisions

No edit summary |

(major transfer from Talk:Hardware specification content) |

||

| Line 1: | Line 1: | ||

'''NOTE:''' Except for [[#Hand Crank Problems]] all items have been imported from [[Talk:Hardware specification]]. --[[User:Xavi|Xavi]] 22:01, 18 January 2007 (EST) |

|||

==Hand Crank Problems== |

==Hand Crank Problems== |

||

I bought a small battery-powered radio with a hand-crank charger to experiment with human-powered devices. It cost me all of £15 at Maplins in the UK. After working with it for a week I have discovered two problems with hand-cranked power. --[[User:Memracom|Memracom]] 16:34, 21 June 2006 (EDT) |

I bought a small battery-powered radio with a hand-crank charger to experiment with human-powered devices. It cost me all of £15 at Maplins in the UK. After working with it for a week I have discovered two problems with hand-cranked power. --[[User:Memracom|Memracom]] 16:34, 21 June 2006 (EDT) |

||

:Added to article. [[User:Tom Haws|Tom Haws]] 13:17, 5 January 2007 (EST) |

:Added to article. [[User:Tom Haws|Tom Haws]] 13:17, 5 January 2007 (EST) |

||

== Power Requirement == |

|||

I see that you have settled on a 14 volt power specification. I think that is a mistake. Living in West Africa for many years now I see that people are very comfortable with 12volt power systems. In almost every remote village one can find an enterprizing person who has fitted out a small TV to run on a car battery. Eventhough there are no solar panels or other power systems in thier village, they will use that battery to run thier "cinama" and then strap that car battery on the back of a bicycle and pedel 20km or more to a town that has some power and a battery charger. |

|||

Making the power system 14 volts then mismatches your device with a well understood and locally vibrant technology, that is unless your specification is so "loose" that the device will run on 12 volts. - eu |

|||

Please specify the 14 volt power with the allowable voltage tolerance. The unloading end voltage of a 6 cell lead-acid battery (which is probably the most widely spread) is at about 11.8 V (say '''11.6 Volt''' including some resistive voltage drop until it reaches the device) so a specification of a 14V (-18%) would be fine for the lower limit. As written above (eu) 12V is the sweet spot of available voltages. It is very important not to miss it, rather consider going for '''7 NiMH''' cells instead of 8 NiMH cells! - ff |

|||

<i>Specs have changed since this comment was noted. Actually, we're using 5 NiMH cells; and the machine will take almost anything above that voltage, to 24 volts, + or - for charging - jg</i> |

|||

== Maximum power: 500 mA (total) == |

|||

This information given on the hardware specification is most likely uncorrect. A current (Ampere) is not a power (Watt) and a maximum current of 500 mA would lead to a very long time to reach full charge if the laptop is on. Probably the stated 500 mA refer to the maximum output current of the USB ports? |

|||

:This is a good point. What is the power usage of the XO? [[User:Tom Haws|Tom Haws]] 14:44, 5 January 2007 (EST) |

|||

== Built in Crank Handle == |

|||

I suggest that you re-visit the idea of a built in crank handle. While the power output of a built in crank is pretty low and the stresses caused on the body of the laptop can be extremely high I have spent time where power is difficult to come by. The built in crank gives users the ability to power when no other power is possible, even if the crank time/use time is as poor as 1/2. |

|||

:There will be a human-power option, but we've moved it off the laptop itself. I twill be part of the power adaptor. [[User:Walter|Walter]] 14:17, 30 July 2006 (EDT) |

|||

I would also suggest that you make it possible to connect bare wires to the laptop for power with connectors similar to, but much more rugged, as those on speakers. This gives people the ability to connect to a variety of power sources without cannibalizing the standard power cable. They can use almost anything. You would need to include some kind of reset for when the power fluctuates outside of acceptable ranges. |

|||

:We've considered something along the lones of banana plugs and may revisit it in Gen. 2. [[User:Walter|Walter]] 14:17, 30 July 2006 (EDT) |

|||

Power in third world areas is usually very dirty when available. In the industrialized world we have access to reasonably clean power and still have dirty power issues with computers and computerized machines. I think anyone who believes that accessories and power will be available is naive about third world nations. The nicer places that many people go visit may have some intermittent basic services and this gives people a false understanding of the availability of services in third world nations. As another person pointed out, people will bicycle to a place with power rather than fabricate a charging system for a 12V battery out of a bicycle. |

|||

:We are trying to build as much flexibility into the human-power system as we can so that it can support and foster local innovation. We've also built in extra robustness into the entire power system with the expectation of "dirty" power. [[User:Walter|Walter]] 14:17, 30 July 2006 (EDT) |

|||

You may want to consider including instructions on how to fabricate things in the flash memory of these laptops. Old style Mother Earth News and Peace Corp style fabrication and instructions. |

|||

:Excellent idea!! [[User:Walter|Walter]] 14:17, 30 July 2006 (EDT) |

|||

Awesome project. |

|||

== Crank as an Input Device, and Vice-Versa == |

|||

I request that it be possible to use the crank as an input device. I realise with moving the device off the computer this becomes more difficult, but even a simple way for software to read the amount of voltage currently being generated (measured in seconds, not hours) would be useful. |

|||

Let me give you an extreme example of where I'm going... A computer powered by a mouse, or a computer powered by a joystick, and also with other more interesting user interfaces. In fast action games this might produce a fair amount of power. |

|||

But what I am suggesting now is a much more limited "turn the crank to see next page of ebook" kind of design, where cranking is built in to the application usage model rather than being seen as an added burden. It would also be integrated into gaming, for example foot-pedaling the generator might move your character forwards in a game. This is partly for the purposes of training kids in cranking, and also partly for making the system more immersive and for exploring novel user interface techniques. It also adds a level of physical exercise and interaction into computers that I think is missing, and which might be expected from game players in other countries. |

|||

:The battery will give us a lot more/better information than most laptop batteries. People have already been thinking of doing games with the information. Also, we have a string pull generator device that should be much more effective than most cranks. [[User:jg|Jim Gettys]] |

|||

== 14V DC or 10V DC? Why up to 25V? == |

|||

I'm a bit confused here. 8 AA NiMH cells, in series, discharge at 10V DC and would be charged with something like 11.6V. So why 14V DC? |

|||

Now the battery pack is a 6 cell. |

|||

This will need bare minimum of 12V to charge decently and 12.5V would be better. |

|||

10V will not be able to charge the battery. |

|||

Is there really a need to accept 25V input? This will complicate the charger |

|||

as it will need to be a switching regulator rather than a linear regulator |

|||

or you will have a lot of extra heat. |

|||

<i>We're ending up with 5 cells, after all is said and done. It turns out it is always easier to down convert voltage than handle both up and down. And we can go to about 25 volts before incurring any additional cost, so we're doing so. The polarity is also protected, so that you can't damage the machine by plugging it into the voltage source backwards. </i> |

|||

What will happen to the unit if 110V or 240V AC power is plugged or shorted directly into its power input? There are many levels on which this could be dealt with, e.g.: A. Machine charges using some of the available energy. B. Machine doesn't charge, but doesn't break. C. Machine breaks but doesn't let out toxic smoke. D. Machine breaks, catches fire, and spews melted plastic and rubber on foolish child. E. When out-of-spec power is supplied, machine screams (audio) for help before breaking ten or twenty seconds later. |

|||

While "testing to destruction" those 500 units, you should also try plugging AC power into each of the other ports (USB & audio). Pour kool-aid into the "ears" while AC |

|||

power is applied to the audio port. Wash the laptop with harsh soap and a scrub brush every week. Swim across a lake while toting a laptop on a strap (while it's got an ebook open and is playing music). Move the laptop close to a fire (close enough to not need a backlight to read it) and see what melts first. Hmm, I wonder if you could |

|||

generate power from heat, e.g. an attachment that a kid could toss on the woodstove or in a fire that plugs into the power port. Etc. The imaginations of kids are unlimited. |

|||

Question: why 25 Volts? If 'by accident' connected to a truck (nominal voltage 24 volts), the OLPC will be slightly overloaded (up to 28 volts approx.). Suggestion: a maximum of 30 volts would be fine. What about a bridge rectifier, this would allow simple chargers (mains transformer, manually/'pedually' operated generator etc.) and would eliminate any revers polarity problems. |

|||

<i>The testing is very extensive. I liked particularly when Quanta explained the conventional keyboard test, which was of order "take a cup of coffee, with cream and sugar, and pour it between the g and h keys..." |

|||

So above and beyond the "usual" testing of this order that they do for "normal" laptops, we added quite a bit of additional testing: wider temperature ranges, higher falls, and so on. |

|||

And yes, it has a bridge rectifier; we were talking about nominal input voltages; people understand that truck batteries, nominally 24 volts, actually provide more, and generators are very spikey indeed. |

|||

</i> |

|||

== Battery Type/Voltage == |

|||

The battery pack should accept AA NmH cells, that can be replaced by the teacher. These can also be purchased at a reasonable price, as opposed to a "battery pack". 10 cells equals 12 volts, as said elsewhere this is a standard that should be adhered to. Allowing a 12v input would not charge the battery properly, but this could be connected to a larger (sealed lead acid) battery. With 2.2 AH cells, and a 12 watt consumption, what is the actual operating life of the battery? If teachers are reading this, this is important to them. |

|||

This is a link to a page that talks about an electricity generator that could improve your laptop project |

|||

http://www.lacapital.com.ar/2006/03/08/general/noticia_275466.shtml |

|||

I hope it helps!!! |

|||

<i>We had the same naive view when we started. The problem is, with multiple cells, the connection between cells is not reliable. And computers, rather than flashlights, must have absolutely reliable contacts in their batteries. We do hope the battery packs won't be very hard to service in the field, however. On top of this, UL won't certify anything in the separate cell vein, even if it worked. And we want to be able to swap packs quickly, not with a pile of batteries which can be inserted in the wrong direction. It also looks like 2000 cycles is possible on the cells, by care in the charging circuitry. - jg</i> |

|||

:Your design already supports AA NiMH cells without any change to the design. For years people have been using external battery packs to charge (or extend use time) of PDAs and digital cameras. The OLPC will be no different, especially if someone can rig up a battery pack out of overripe bananas and seawater or something similar. Same goes for charging. Somebody is going to refit electric motors to make DC charging units that you can hook up to your water-buffalo. Your design allows a wide range of power inputs to be safely applied and that gives it maximum flexibility. |

|||

I'm not so sure I agree with the FUD on the page about the batteries. ("High charging efficiency", "no environmental concerns", "no safety problems", "removable packs being cheaper") If you're picking NiMH, but not picking a format that can use readily available cells as has been mentioned, I only see one reason to use NiMH over LiIon, and that reason isn't even mentioned at all. |

|||

Charging LiIon is easier than charging NiMH. In either case you can't just pump energy into either container at will -- you'll have to throttle them both. But the end-of-charge detection for one chemistry is much easier than the other, as far as I can tell. |

|||

And that's not the worst of the problems. If you're going to use typical NiMH cells, you only get 1.2V per cell. You'll have to gang them up in series to get the voltage you want. The worst thing about NiMH packs is the fact that a single cell in the pack can start to get weak and really hurt the pack due to charge/discharge differences. Over the course of charge/discharge cycles, this problem is exacerbated, leading to a self-toasting pack. I don't see that these packs are user-serviceable, so in the end, how can this be better for the environment? |

|||

This is assuming you don't put taps in between each of the cells (4 for a 5 cell pack) to make sure imbalances don't happen and don't propagate. How can this be easier or cheaper than, say, a 2 cell lithium ion pack which only needs one tap to track the cells, and has an easier end-of-charge detection mechanism for each cell? |

|||

As far as safety is concerned, these are energy storage devices, and they can both blow up. Some people might refer to the recent hubbub with Apple/Dell battery packs, but I think those are somewhat special cases (more social than technical). Bear in mind that lithium ion has been happily powering our camcorders and other electronic devices for a long time without blowing up. Where was the rash of camcorder fires? What about cell phones melting down? On top of that, lithium technology has gotten better, and is still getting better. |

|||

And while we are on that subject... why exactly are you designing a new pack to begin with? Why can't you use an already existing format? OK, so you supposedly have reasons to not use single-cell AA's. What's wrong with, say... camcorder battery packs? It's clear that manufacturers already know how to make those quite cheaply, and they have guard circuitry built into them and everything. The chargers are already widespread as well. This one I really don't get. |

|||

-- |

|||

Battery selection and risks... |

|||

I argue that NiMH are actually less safe than Lithium but currently cost less per/Wh and can be used for more charge/discharge cycles. |

|||

I realize this is all just talk because the product is likely too far along to be making major changes to it. Even so... |

|||

In our experience, lithium is more reliable and produces less service requirements in the field. The company I started sells battery operated LED flashlights with boost circuitry that operate at high drain currents and can use alkaline, NiMH or Lithium cells (the customer can pick). We don't make the battery. The number one reason for warranty service is for battery leakage and corrosive damage of the innards. The failures are highest with alkaline (even adjusted for usage numbers) and second highest with NiMH. I have had lightly used NiMH ooze, burst and very loudly explode while charging in the recommended name brand charger. We recommend our customers use rechargeable Lithium because not only will they get better performance but it saves us money in service. |

|||

Although lithium is in the news right now, media perception is different than the real world data. Our tests indicate that regardless of the chemistry, most problems occur with cells when they are used in packs. Series connection is especially risky. Notice how most cell phones now use single cell lithium. |

|||

The problem with packs is cell balancing and reduced failure tolerance. The problems increase in a non-linear fashion as the number of cells is increased. Most laptops are power hogs and therefore require a large volume battery made up of multiple standard-sized (16850, etc) cells. Safety can be increased by dedicating battery management electronics for each cell in a multi-cell pack, buts risks are still higher than with a single cell system. |

|||

You will likely find that a 5 cell NiMh pack will be more service intensive in the field than a single cell Lithium. |

|||

Although boost (step-up) voltage conversion is typically 5-10% less efficient than buck (step-down) conversion, the increased safety of a single cell can be worth the effort. |

|||

A Lithium Ion cell is 4.2v open circuit and 3.7v under typical load. Most laptops require various voltages like 5v for the USB interface, 3.3v, etc. Those are all produced by the power management section using standard regulated boost converters. Note the modern PDA phone with USB port, flash memory, color lcd, etc all powered by a single lithium cell. |

|||

Compared to NiMh, I argue that lithium are safer, easier to charge, have a lower self discharge, wider temperature range and weigh less. Disadvantages include less cycle life (current cells achieve about 500 cycles compared to 2000 for NiMh but new lithium cells entering production have cycle lifes of over 4000 cycles) and cost. I realize cost/Wh is an especially big ding. You have to weigh it against the real world costs of fielding a system and the repercussions from its use. |

|||

My recommendation is to use a common cell phone pack from a reputable manufacturer. A typical pack is rated at 900-1200mAh(3-4Wh). Yes, I realize your current NiMh pack is rated at 22.8Wh. But I assume that most of that capacity is for runtime and to meet the maximum current consumption. You rate the maximum current consumption as 500mA; although I think you were referring to the USB port capability (500mA is the maximum standard output of a USB port). I apologize if I misunderstand. In other literature you refer to the 5W maximum system usage. At 10v, 500mA equals 5W, so I will assume 5w for my estimates, (1.4A at 3.6v). At max power consumption, a single 1Ah pack like in my LG would only last about 30 minutes. But at a more typical consumption, it would last over 2 hours. Just a suggestion; the compartment for the battery pack could include multiple sockets for various pack standards if need be. A 4-way compartment with water resistant door is one idea. Such a system would be smaller than the current pack. It could also be designed so that multiple cells can be connected at (in parallel) to increase run time. Or the child could simply swap out the cell for a spare. I would prefer less swapping if possible since that fatigues the connectors. Reducing the c rate on the cell also increases its cycle life and mAh delivery. This favors a system with 2 cells, switched in one at a time as needed. A standard cell phone pack has a built-in management ic for monitoring temperature, columb usage for the battery guage, etc. You will notice that originally phone models had all types of packs but the trend has been towards a standardization of the pack design using a 3.7v prismatic cell stored behind a compartment door. |

|||

I recall that one of the program goals was to have the battery last throughout a typical school day. If average consumption was 1.5Wh per hour, 2, common 1000mAh packs stored internally would last over 4 hours. |

|||

Notice how quickly cell phones appear in developing countries. You will probably find that cell phones are already in country before laptops are. This means there is already some sort of infrastructure for the sale and care of these packs. |

|||

Misc notes: |

|||

<br>- An AA or AAA battery adapter could be designed. The AA alkaline is the most common battery in the world. |

|||

<br>- The 24v +- max input and polarity protection could be maintained. The minimum voltage of 10v could also be extended down to 3v if necessary by switching in the internal boost circuit. This would be helpful for tapping 6v scooter(motorcycle) batteries, etc. |

|||

<br>- I assume the current system allows for operation with the battery removed and external dc connected. This could be important if the generator continued to work but the battery had failed. |

|||

<br>- Using common cell phone batteries would support local companies, street vendors, etc. Introducing a proprietary pack in large numbers may be disruptive. |

|||

<br> - In my experience, most mechanical generators (crank, foot, etc) are only good for emergency use. Prolonged use causes them to fail. Gears strip, bearings fail, etc. Hopefully you can field a reliable system. Solar would be nice and reliable for most locations. Like the common 12v amorphous battery maintenance models (1-2W, less than $35) with plug to fit the dc jack on the laptop. |

|||

edit- |

|||

I did a quick search for 10k pricing on a standard 1200mA prismatic Lithium Ion and found them for less than $4 each. Sizes above 2Ah could be had but were less standard. So price may actually be in favor of the lithium. I suspect the fact that these packs are used in cell phones and cell phones are a large market phenomena, pricing per Wh is very competitive compared to proprietary packs. |

|||

I recommend resisting the temptation to put the 2 cells in series. That would significantly increase support issues IMO. Especially considering the market and typical user. With each pack having an internal protection ic (standard), the packs could be connected in parallel so that the power management on the main board is simplified. If one cell croaked, its ic would take it offline and send an error up the i2c buss. Again, standard stuff thanks to the cell phone industry. The laptop could continue to operate on the remaining cell with no interruption. A little window could pop and provide a helpful message about what to do with the pack, etc. Compare this to a system with only pack, multiple cells in series (weak links), suddenly failing in class while the poor student tries pressing the power button repeatidly (they have no idea why it failed), etc. |

|||

peter@gransee.com |

|||

== power generation during walking using suspended load backpack? == |

|||

You've probably already rejected this, but I was intrigued to see a scientific american article (Septmber 9, 2005 " Pounding Pavement Generates Electricity When Wearing Novel Backpack |

|||

") about a backpack that generated power through a 'suspended load' backpack, converting up/down motion into power - 20kg (a lot I know) loads generated around 7W - i.e. power generated by walking to school (or by asking anyone else to wear it e.g. football game). Worth considering the empowerment of a kid not having to ask anyone else for help with power - I imagine the backpack might cost more than the computer, but here's the link anyway |

|||

==Power generation, battery, and leg power== |

|||

Jim, Walter, and group, I am new here. I have followed the OLPC project all along, but have never given any input. I'm a civil engineer with a high interest in humanitarian and spiritual work and energy development. I have a few questions: [[User:Tom Haws|Tom Haws]] 15:58, 5 January 2007 (EST) |

|||

===Leg power=== |

|||

What thought has been given to possibly learning from and imitating the real world successes of the treadle sewing machine (mentioned already) and the pump organ (not mentioned anywhere I could see)? [[User:Tom Haws|Tom Haws]] |

|||

* Legs have more strength than hands or arms. Mechanical power input could range from 2 to 40 watts depending on the level of conscious effort. [[User:Tom Haws|Tom Haws]] |

|||

* Legs have stamina that exceeds computing demand. Continuous mechanical power of 4 watts can be sustained by a movement of 2 cm at 2 Hz under 50 Newtons (10 lb.) of tension by both legs. [[User:Tom Haws|Tom Haws]] |

|||

* Leg power generation doesn't interrupt work (this is why treadle sewing machines and pump organs are successful) [[User:Tom Haws|Tom Haws]] |

|||

What is the disposition of the OLPC team to date toward treadle/pumping action? [[User:Tom Haws|Tom Haws]] |

|||

Is the Potenco generator ideally suited for treadle/pumping action, or would another design work better? [[User:Tom Haws|Tom Haws]] |

|||

[[Image:Treadle_rocker_sketch.png|Treadle rocker generator]] |

|||

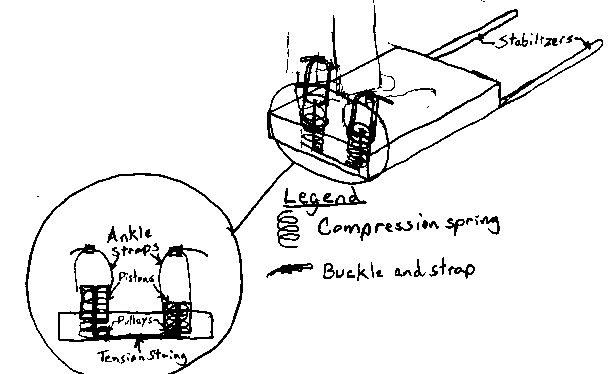

A second idea that is much harder to draw (does that mean it's worse?), but more ergonomic is a piston and pulley treadle. [[User:Tom Haws|Tom Haws]] |

|||

[[Image:Treadle_piston_pulley_sketch.png|Treadle piston and pulley generator]] |

|||

Is anything along these lines under discussion, or is OLPC much further advanced than this? [[User:Tom Haws|Tom Haws]] 16:40, 5 January 2007 (EST) |

|||

===Battery=== |

|||

What thought has been given to the idea of removing the battery from the chassis of the XO? [[User:Tom Haws|Tom Haws]] 15:58, 5 January 2007 (EST) |

|||

What cost benefit would there be to removing the battery from the XO chassis? [[User:Tom Haws|Tom Haws]] |

|||

Would it make sense to delegate to purchasers the selection of power source, whether AC/DC transformed grid power, exernally charge battery, or OLPC generator power pack? |

|||

Revision as of 03:01, 19 January 2007

NOTE: Except for #Hand Crank Problems all items have been imported from Talk:Hardware specification. --Xavi 22:01, 18 January 2007 (EST)

Hand Crank Problems

I bought a small battery-powered radio with a hand-crank charger to experiment with human-powered devices. It cost me all of £15 at Maplins in the UK. After working with it for a week I have discovered two problems with hand-cranked power. --Memracom 16:34, 21 June 2006 (EDT)

- Added to article. Tom Haws 13:17, 5 January 2007 (EST)

Power Requirement

I see that you have settled on a 14 volt power specification. I think that is a mistake. Living in West Africa for many years now I see that people are very comfortable with 12volt power systems. In almost every remote village one can find an enterprizing person who has fitted out a small TV to run on a car battery. Eventhough there are no solar panels or other power systems in thier village, they will use that battery to run thier "cinama" and then strap that car battery on the back of a bicycle and pedel 20km or more to a town that has some power and a battery charger.

Making the power system 14 volts then mismatches your device with a well understood and locally vibrant technology, that is unless your specification is so "loose" that the device will run on 12 volts. - eu

Please specify the 14 volt power with the allowable voltage tolerance. The unloading end voltage of a 6 cell lead-acid battery (which is probably the most widely spread) is at about 11.8 V (say 11.6 Volt including some resistive voltage drop until it reaches the device) so a specification of a 14V (-18%) would be fine for the lower limit. As written above (eu) 12V is the sweet spot of available voltages. It is very important not to miss it, rather consider going for 7 NiMH cells instead of 8 NiMH cells! - ff

Specs have changed since this comment was noted. Actually, we're using 5 NiMH cells; and the machine will take almost anything above that voltage, to 24 volts, + or - for charging - jg

Maximum power: 500 mA (total)

This information given on the hardware specification is most likely uncorrect. A current (Ampere) is not a power (Watt) and a maximum current of 500 mA would lead to a very long time to reach full charge if the laptop is on. Probably the stated 500 mA refer to the maximum output current of the USB ports?

- This is a good point. What is the power usage of the XO? Tom Haws 14:44, 5 January 2007 (EST)

Built in Crank Handle

I suggest that you re-visit the idea of a built in crank handle. While the power output of a built in crank is pretty low and the stresses caused on the body of the laptop can be extremely high I have spent time where power is difficult to come by. The built in crank gives users the ability to power when no other power is possible, even if the crank time/use time is as poor as 1/2.

- There will be a human-power option, but we've moved it off the laptop itself. I twill be part of the power adaptor. Walter 14:17, 30 July 2006 (EDT)

I would also suggest that you make it possible to connect bare wires to the laptop for power with connectors similar to, but much more rugged, as those on speakers. This gives people the ability to connect to a variety of power sources without cannibalizing the standard power cable. They can use almost anything. You would need to include some kind of reset for when the power fluctuates outside of acceptable ranges.

- We've considered something along the lones of banana plugs and may revisit it in Gen. 2. Walter 14:17, 30 July 2006 (EDT)

Power in third world areas is usually very dirty when available. In the industrialized world we have access to reasonably clean power and still have dirty power issues with computers and computerized machines. I think anyone who believes that accessories and power will be available is naive about third world nations. The nicer places that many people go visit may have some intermittent basic services and this gives people a false understanding of the availability of services in third world nations. As another person pointed out, people will bicycle to a place with power rather than fabricate a charging system for a 12V battery out of a bicycle.

- We are trying to build as much flexibility into the human-power system as we can so that it can support and foster local innovation. We've also built in extra robustness into the entire power system with the expectation of "dirty" power. Walter 14:17, 30 July 2006 (EDT)

You may want to consider including instructions on how to fabricate things in the flash memory of these laptops. Old style Mother Earth News and Peace Corp style fabrication and instructions.

- Excellent idea!! Walter 14:17, 30 July 2006 (EDT)

Awesome project.

Crank as an Input Device, and Vice-Versa

I request that it be possible to use the crank as an input device. I realise with moving the device off the computer this becomes more difficult, but even a simple way for software to read the amount of voltage currently being generated (measured in seconds, not hours) would be useful.

Let me give you an extreme example of where I'm going... A computer powered by a mouse, or a computer powered by a joystick, and also with other more interesting user interfaces. In fast action games this might produce a fair amount of power.

But what I am suggesting now is a much more limited "turn the crank to see next page of ebook" kind of design, where cranking is built in to the application usage model rather than being seen as an added burden. It would also be integrated into gaming, for example foot-pedaling the generator might move your character forwards in a game. This is partly for the purposes of training kids in cranking, and also partly for making the system more immersive and for exploring novel user interface techniques. It also adds a level of physical exercise and interaction into computers that I think is missing, and which might be expected from game players in other countries.

- The battery will give us a lot more/better information than most laptop batteries. People have already been thinking of doing games with the information. Also, we have a string pull generator device that should be much more effective than most cranks. Jim Gettys

14V DC or 10V DC? Why up to 25V?

I'm a bit confused here. 8 AA NiMH cells, in series, discharge at 10V DC and would be charged with something like 11.6V. So why 14V DC?

Now the battery pack is a 6 cell. This will need bare minimum of 12V to charge decently and 12.5V would be better. 10V will not be able to charge the battery.

Is there really a need to accept 25V input? This will complicate the charger as it will need to be a switching regulator rather than a linear regulator or you will have a lot of extra heat.

We're ending up with 5 cells, after all is said and done. It turns out it is always easier to down convert voltage than handle both up and down. And we can go to about 25 volts before incurring any additional cost, so we're doing so. The polarity is also protected, so that you can't damage the machine by plugging it into the voltage source backwards.

What will happen to the unit if 110V or 240V AC power is plugged or shorted directly into its power input? There are many levels on which this could be dealt with, e.g.: A. Machine charges using some of the available energy. B. Machine doesn't charge, but doesn't break. C. Machine breaks but doesn't let out toxic smoke. D. Machine breaks, catches fire, and spews melted plastic and rubber on foolish child. E. When out-of-spec power is supplied, machine screams (audio) for help before breaking ten or twenty seconds later.

While "testing to destruction" those 500 units, you should also try plugging AC power into each of the other ports (USB & audio). Pour kool-aid into the "ears" while AC power is applied to the audio port. Wash the laptop with harsh soap and a scrub brush every week. Swim across a lake while toting a laptop on a strap (while it's got an ebook open and is playing music). Move the laptop close to a fire (close enough to not need a backlight to read it) and see what melts first. Hmm, I wonder if you could generate power from heat, e.g. an attachment that a kid could toss on the woodstove or in a fire that plugs into the power port. Etc. The imaginations of kids are unlimited.

Question: why 25 Volts? If 'by accident' connected to a truck (nominal voltage 24 volts), the OLPC will be slightly overloaded (up to 28 volts approx.). Suggestion: a maximum of 30 volts would be fine. What about a bridge rectifier, this would allow simple chargers (mains transformer, manually/'pedually' operated generator etc.) and would eliminate any revers polarity problems.

The testing is very extensive. I liked particularly when Quanta explained the conventional keyboard test, which was of order "take a cup of coffee, with cream and sugar, and pour it between the g and h keys..."

So above and beyond the "usual" testing of this order that they do for "normal" laptops, we added quite a bit of additional testing: wider temperature ranges, higher falls, and so on.

And yes, it has a bridge rectifier; we were talking about nominal input voltages; people understand that truck batteries, nominally 24 volts, actually provide more, and generators are very spikey indeed.

Battery Type/Voltage

The battery pack should accept AA NmH cells, that can be replaced by the teacher. These can also be purchased at a reasonable price, as opposed to a "battery pack". 10 cells equals 12 volts, as said elsewhere this is a standard that should be adhered to. Allowing a 12v input would not charge the battery properly, but this could be connected to a larger (sealed lead acid) battery. With 2.2 AH cells, and a 12 watt consumption, what is the actual operating life of the battery? If teachers are reading this, this is important to them.

This is a link to a page that talks about an electricity generator that could improve your laptop project http://www.lacapital.com.ar/2006/03/08/general/noticia_275466.shtml

I hope it helps!!!

We had the same naive view when we started. The problem is, with multiple cells, the connection between cells is not reliable. And computers, rather than flashlights, must have absolutely reliable contacts in their batteries. We do hope the battery packs won't be very hard to service in the field, however. On top of this, UL won't certify anything in the separate cell vein, even if it worked. And we want to be able to swap packs quickly, not with a pile of batteries which can be inserted in the wrong direction. It also looks like 2000 cycles is possible on the cells, by care in the charging circuitry. - jg

- Your design already supports AA NiMH cells without any change to the design. For years people have been using external battery packs to charge (or extend use time) of PDAs and digital cameras. The OLPC will be no different, especially if someone can rig up a battery pack out of overripe bananas and seawater or something similar. Same goes for charging. Somebody is going to refit electric motors to make DC charging units that you can hook up to your water-buffalo. Your design allows a wide range of power inputs to be safely applied and that gives it maximum flexibility.

I'm not so sure I agree with the FUD on the page about the batteries. ("High charging efficiency", "no environmental concerns", "no safety problems", "removable packs being cheaper") If you're picking NiMH, but not picking a format that can use readily available cells as has been mentioned, I only see one reason to use NiMH over LiIon, and that reason isn't even mentioned at all.

Charging LiIon is easier than charging NiMH. In either case you can't just pump energy into either container at will -- you'll have to throttle them both. But the end-of-charge detection for one chemistry is much easier than the other, as far as I can tell.

And that's not the worst of the problems. If you're going to use typical NiMH cells, you only get 1.2V per cell. You'll have to gang them up in series to get the voltage you want. The worst thing about NiMH packs is the fact that a single cell in the pack can start to get weak and really hurt the pack due to charge/discharge differences. Over the course of charge/discharge cycles, this problem is exacerbated, leading to a self-toasting pack. I don't see that these packs are user-serviceable, so in the end, how can this be better for the environment?

This is assuming you don't put taps in between each of the cells (4 for a 5 cell pack) to make sure imbalances don't happen and don't propagate. How can this be easier or cheaper than, say, a 2 cell lithium ion pack which only needs one tap to track the cells, and has an easier end-of-charge detection mechanism for each cell?

As far as safety is concerned, these are energy storage devices, and they can both blow up. Some people might refer to the recent hubbub with Apple/Dell battery packs, but I think those are somewhat special cases (more social than technical). Bear in mind that lithium ion has been happily powering our camcorders and other electronic devices for a long time without blowing up. Where was the rash of camcorder fires? What about cell phones melting down? On top of that, lithium technology has gotten better, and is still getting better.

And while we are on that subject... why exactly are you designing a new pack to begin with? Why can't you use an already existing format? OK, so you supposedly have reasons to not use single-cell AA's. What's wrong with, say... camcorder battery packs? It's clear that manufacturers already know how to make those quite cheaply, and they have guard circuitry built into them and everything. The chargers are already widespread as well. This one I really don't get.

--

Battery selection and risks...

I argue that NiMH are actually less safe than Lithium but currently cost less per/Wh and can be used for more charge/discharge cycles.

I realize this is all just talk because the product is likely too far along to be making major changes to it. Even so...

In our experience, lithium is more reliable and produces less service requirements in the field. The company I started sells battery operated LED flashlights with boost circuitry that operate at high drain currents and can use alkaline, NiMH or Lithium cells (the customer can pick). We don't make the battery. The number one reason for warranty service is for battery leakage and corrosive damage of the innards. The failures are highest with alkaline (even adjusted for usage numbers) and second highest with NiMH. I have had lightly used NiMH ooze, burst and very loudly explode while charging in the recommended name brand charger. We recommend our customers use rechargeable Lithium because not only will they get better performance but it saves us money in service.

Although lithium is in the news right now, media perception is different than the real world data. Our tests indicate that regardless of the chemistry, most problems occur with cells when they are used in packs. Series connection is especially risky. Notice how most cell phones now use single cell lithium.

The problem with packs is cell balancing and reduced failure tolerance. The problems increase in a non-linear fashion as the number of cells is increased. Most laptops are power hogs and therefore require a large volume battery made up of multiple standard-sized (16850, etc) cells. Safety can be increased by dedicating battery management electronics for each cell in a multi-cell pack, buts risks are still higher than with a single cell system.

You will likely find that a 5 cell NiMh pack will be more service intensive in the field than a single cell Lithium.

Although boost (step-up) voltage conversion is typically 5-10% less efficient than buck (step-down) conversion, the increased safety of a single cell can be worth the effort.

A Lithium Ion cell is 4.2v open circuit and 3.7v under typical load. Most laptops require various voltages like 5v for the USB interface, 3.3v, etc. Those are all produced by the power management section using standard regulated boost converters. Note the modern PDA phone with USB port, flash memory, color lcd, etc all powered by a single lithium cell.

Compared to NiMh, I argue that lithium are safer, easier to charge, have a lower self discharge, wider temperature range and weigh less. Disadvantages include less cycle life (current cells achieve about 500 cycles compared to 2000 for NiMh but new lithium cells entering production have cycle lifes of over 4000 cycles) and cost. I realize cost/Wh is an especially big ding. You have to weigh it against the real world costs of fielding a system and the repercussions from its use.

My recommendation is to use a common cell phone pack from a reputable manufacturer. A typical pack is rated at 900-1200mAh(3-4Wh). Yes, I realize your current NiMh pack is rated at 22.8Wh. But I assume that most of that capacity is for runtime and to meet the maximum current consumption. You rate the maximum current consumption as 500mA; although I think you were referring to the USB port capability (500mA is the maximum standard output of a USB port). I apologize if I misunderstand. In other literature you refer to the 5W maximum system usage. At 10v, 500mA equals 5W, so I will assume 5w for my estimates, (1.4A at 3.6v). At max power consumption, a single 1Ah pack like in my LG would only last about 30 minutes. But at a more typical consumption, it would last over 2 hours. Just a suggestion; the compartment for the battery pack could include multiple sockets for various pack standards if need be. A 4-way compartment with water resistant door is one idea. Such a system would be smaller than the current pack. It could also be designed so that multiple cells can be connected at (in parallel) to increase run time. Or the child could simply swap out the cell for a spare. I would prefer less swapping if possible since that fatigues the connectors. Reducing the c rate on the cell also increases its cycle life and mAh delivery. This favors a system with 2 cells, switched in one at a time as needed. A standard cell phone pack has a built-in management ic for monitoring temperature, columb usage for the battery guage, etc. You will notice that originally phone models had all types of packs but the trend has been towards a standardization of the pack design using a 3.7v prismatic cell stored behind a compartment door.

I recall that one of the program goals was to have the battery last throughout a typical school day. If average consumption was 1.5Wh per hour, 2, common 1000mAh packs stored internally would last over 4 hours.

Notice how quickly cell phones appear in developing countries. You will probably find that cell phones are already in country before laptops are. This means there is already some sort of infrastructure for the sale and care of these packs.

Misc notes:

- An AA or AAA battery adapter could be designed. The AA alkaline is the most common battery in the world.

- The 24v +- max input and polarity protection could be maintained. The minimum voltage of 10v could also be extended down to 3v if necessary by switching in the internal boost circuit. This would be helpful for tapping 6v scooter(motorcycle) batteries, etc.

- I assume the current system allows for operation with the battery removed and external dc connected. This could be important if the generator continued to work but the battery had failed.

- Using common cell phone batteries would support local companies, street vendors, etc. Introducing a proprietary pack in large numbers may be disruptive.

- In my experience, most mechanical generators (crank, foot, etc) are only good for emergency use. Prolonged use causes them to fail. Gears strip, bearings fail, etc. Hopefully you can field a reliable system. Solar would be nice and reliable for most locations. Like the common 12v amorphous battery maintenance models (1-2W, less than $35) with plug to fit the dc jack on the laptop.

edit- I did a quick search for 10k pricing on a standard 1200mA prismatic Lithium Ion and found them for less than $4 each. Sizes above 2Ah could be had but were less standard. So price may actually be in favor of the lithium. I suspect the fact that these packs are used in cell phones and cell phones are a large market phenomena, pricing per Wh is very competitive compared to proprietary packs.

I recommend resisting the temptation to put the 2 cells in series. That would significantly increase support issues IMO. Especially considering the market and typical user. With each pack having an internal protection ic (standard), the packs could be connected in parallel so that the power management on the main board is simplified. If one cell croaked, its ic would take it offline and send an error up the i2c buss. Again, standard stuff thanks to the cell phone industry. The laptop could continue to operate on the remaining cell with no interruption. A little window could pop and provide a helpful message about what to do with the pack, etc. Compare this to a system with only pack, multiple cells in series (weak links), suddenly failing in class while the poor student tries pressing the power button repeatidly (they have no idea why it failed), etc.

peter@gransee.com

power generation during walking using suspended load backpack?

You've probably already rejected this, but I was intrigued to see a scientific american article (Septmber 9, 2005 " Pounding Pavement Generates Electricity When Wearing Novel Backpack ") about a backpack that generated power through a 'suspended load' backpack, converting up/down motion into power - 20kg (a lot I know) loads generated around 7W - i.e. power generated by walking to school (or by asking anyone else to wear it e.g. football game). Worth considering the empowerment of a kid not having to ask anyone else for help with power - I imagine the backpack might cost more than the computer, but here's the link anyway

Power generation, battery, and leg power

Jim, Walter, and group, I am new here. I have followed the OLPC project all along, but have never given any input. I'm a civil engineer with a high interest in humanitarian and spiritual work and energy development. I have a few questions: Tom Haws 15:58, 5 January 2007 (EST)

Leg power

What thought has been given to possibly learning from and imitating the real world successes of the treadle sewing machine (mentioned already) and the pump organ (not mentioned anywhere I could see)? Tom Haws

- Legs have more strength than hands or arms. Mechanical power input could range from 2 to 40 watts depending on the level of conscious effort. Tom Haws

- Legs have stamina that exceeds computing demand. Continuous mechanical power of 4 watts can be sustained by a movement of 2 cm at 2 Hz under 50 Newtons (10 lb.) of tension by both legs. Tom Haws

- Leg power generation doesn't interrupt work (this is why treadle sewing machines and pump organs are successful) Tom Haws

What is the disposition of the OLPC team to date toward treadle/pumping action? Tom Haws

Is the Potenco generator ideally suited for treadle/pumping action, or would another design work better? Tom Haws

A second idea that is much harder to draw (does that mean it's worse?), but more ergonomic is a piston and pulley treadle. Tom Haws

Is anything along these lines under discussion, or is OLPC much further advanced than this? Tom Haws 16:40, 5 January 2007 (EST)

Battery

What thought has been given to the idea of removing the battery from the chassis of the XO? Tom Haws 15:58, 5 January 2007 (EST)

What cost benefit would there be to removing the battery from the XO chassis? Tom Haws

Would it make sense to delegate to purchasers the selection of power source, whether AC/DC transformed grid power, exernally charge battery, or OLPC generator power pack?