Multi channel battery charger: Difference between revisions

Jump to navigation

Jump to search

| Line 9: | Line 9: | ||

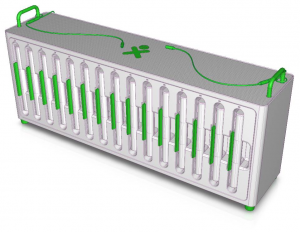

[[Image:Multi-Battery_Charger.png|thumb|Multi-Battery (Gang)Charger]] |

[[Image:Multi-Battery_Charger.png|thumb|Multi-Battery (Gang)Charger]] |

||

== Key |

== Key Specifications == |

||

* 15 batteries per unit. |

* 15 batteries per unit. |

||

* Charge batteries in 2 hours |

* Charge batteries in 2 hours |

||

* AC (120/240V) and DC operation |

|||

* OLPC must own the entire design. |

|||

== Electrical == |

== Electrical == |

||

Revision as of 08:32, 10 February 2008

This page is monitored by the OLPC team.

| NOTE: The contents of this page are not set in stone, and are subject to change! This page is a draft in active flux ... |

Multi Channel Battery Charger

See Product News for product availability.

Key Specifications

- 15 batteries per unit.

- Charge batteries in 2 hours

- AC (120/240V) and DC operation

Electrical

- The CPU will be and Atmel At91SAM7x family part. Either the 128 or 256 depending on how cheap we can get them in volume.

- Power source. AC 100V-230V. DC 9V-30V. The DC plug needs to be some sort of standard plug. Each battery needs 15W if its charged from totally empty. So 15 batteries is 225W. Meaning we will probably need a 300W power supply or so. 9VDC @ 300W means a 30 Amp connector.

Exterior devices

- AC In: IEC for 100 to 220VAC

- DC In: 9VDC to 30VDC 30Amp

- Bill is going to find us a few connectors to choose from.

- DB9 for RS-232

- USB B connector (Its a USB device)

- Power switch

- Need example switches

- In addition to the power switch we are also going to need some sort of circuit breaker on the input. Considering the different voltage/current ranges for AC vs DC there will probably need to be one for each supply.

- Two indicator lights per battery channel

- Red Led and Green Led. Use the same setup as in the laptop. Red, Green, and Yellow both are enabled.

- Battery Tray

- External laptop power DC cables.

- 2 of the XO DC power cables available to the kids so they they can power their laptops while they switch batteries. This keeps them from having to turn off the laptops to switch batteries.

- Future RJ45 10/100 ethernet connection

Software

- will be updated soon

Mechanical

- Density. Getting as many batteries as possible in as small a footprint is a goal.

- Physical Safety. Its got to be stable and hold lots of heavy batteries but not be able to fall over on top of a child. Who might be trying to climb on it to get his battery.

- Stackable. More vertical space is available than floor sq footage so an idea was to make them stackable. But see above point.

- Heat dissipation. Each battery needs 15W worst case and most of that power will be dissipated into the batery. I expect the electronics/battery to dissipate less than 1W/battery. PSU at 300W @ 85% efficiency is 45W.

- Enclosure. Metal. Except perhaps for some plastic for the battery holder. Having metal available to heatsink to should help in keeping the electronics from burning up in hot countries.

Datasheets

- File:At91sam7x128 256 pc.pdf Atmel CPU

- File:DS2756.pdf DS2756

- 30A connector